One of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material.

OPTIMIZING BREAKER EFFICIENCY THROUGH SPARE PARTS

In modern construction, road building, mining, and demolition sectors, hydraulic breakers are among the most critical attachments determining work volume and overall productivity. However, a breaker’s performance is not defined solely by its tonnage or impact energy; it is equally determined by the quality of its spare parts, correct selection, and timely intervention. The most practical way to increase on-site efficiency is to use the correct tool type, keep bushing wear under control, and maintain piston sealing at an optimal level.

THE IMPACT OF CORRECT TOOL SELECTION ON PRODUCTIVITY

The tool is the only component of a hydraulic breaker that comes into direct contact with the ground and transfers energy. For this reason, incorrect tool selection can result in 30–50% of the impact energy being wasted. No matter how powerful a breaker is, productivity can be significantly reduced if the wrong tool is used.

Tool Types and Application Areas

First, pointed (moil) tools are used for cracking rock and concrete, applications requiring deep penetration, and tasks demanding high point impact concentration. Chisel tools are preferred for directional breaking, road cutting, wall demolition, and controlled breaking in concrete by creating cutting lines. Blunt (flat) tools are commonly used for surface breaking of hard rock, applications where energy needs to be distributed over a wider area, and tunnel or quarry operations.

Finally, special design tools include asphalt cutting tools, frozen ground tools, and vibration-based demolition tools. Tool selection is the first and most decisive step in determining breaker efficiency.

The Direct Effect of Tool Selection on Efficiency

One of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material. This leads to performance loss, increased fuel consumption, vibration in the carrier machine, and accelerated wear of bushings and the piston.

From a productivity and time management perspective, correct tool selection shortens breaking time, reduces operator fatigue, and enables more work to be completed per day. For example, using a blunt tool instead of a pointed tool on a hard material such as granite can increase breaking time by up to 60%.

Regarding maintenance costs, an unsuitable tool places unnecessary loads on the bushing and piston. Bushing wear accelerates, scratches may occur on the piston surface, and deformation can be observed in the housing and cap areas. Since these components are high-cost parts, correct tool selection significantly reduces the total cost of ownership. You can easily find the hydraulic breaker tool types you are looking for by brand and model at www.jackhammerparts.com.

THE EFFECT OF BUSHING WEAR ON IMPACT LOSS

The bushing is a critical component that keeps the tool centered inside the housing and protects the hydraulic breaker. A worn bushing directly affects breaker performance. Its primary functions are to keep the tool aligned at the center, transmit piston impacts evenly, absorb side loads, and protect both the housing and piston surface. When the bushing wears, none of these functions operate ideally.

As bushing wear increases, the tool begins to move excessively (“play”) inside the housing. When the tool is no longer centered, several problems arise. Impact loss is the first and most significant issue: every idle or misaligned blow means lower breaking force, longer operation time, and wasted energy. Piston misalignment occurs when the piston no longer moves in a perfect linear path, leading to surface scratches, overheating, and a reduction in impact frequency. Another consequence is increased vibration, which over time weakens the lower and front heads, piston, seal kit, bolts, and the housing frame. The higher the vibration level, the lower the overall efficiency.

Bushing wear has a chain reaction effect:

Worn bushing → piston wear → seal kit failure → accumulator malfunction → loss of impact power.

For this reason, in professional applications, bushing inspection should be carried out every 40–80 operating hours.

PISTON SEALING AND SPEED PERFORMANCE

The piston sealing system is one of the most critical elements in impact generation for a hydraulic breaker. When sealing integrity is compromised, the pressure differential required to control piston movement cannot be maintained, resulting in reduced speed performance. The functions of piston sealing include separating pressure chambers, preventing oil backflow, regulating piston movement speed, and ensuring continuity of impact energy. A seal kit ensures that piston impacts remain stable and consistent. The performance effects of sealing failure include a reduction in blows per minute (BPM). A piston with compromised sealing cannot reach the target impact frequency. Even a 10% decrease in impact frequency can reduce daily productivity by up to 20%. Hydraulic oil leakage disrupts pressure balance, increases oil temperature, and causes the breaker to consume more power. Piston rebound issues also occur, as worn seal surfaces negatively affect piston return speed. Furthermore, energy distribution deterioration means that even minor sealing damage can significantly reduce usable impact energy.

Incorrect tool selection → bushing wear → piston misalignment → piston surface scratches → accelerated seal kit failure → loss of impact power and speed, preventing the piston from operating in an ideal cycle → Accumulator diaphragm wear → reduced impact energy (10–30% loss). For this reason, spare parts management must be considered as an integrated system rather than individual components. With its wide product range and quality-approved components, www.jackhammerparts.com can meet your hydraulic breaker spare part needs efficiently and reliably.

Bu haber 9.1.2026 16:39:16 tarihinde eklenmiştir.

Tool Types and Application Areas

Uç Tipleri ve Uygulama Alanları

Critical Components Of The Piston And Impact Mechanism

Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik Parçaları

Which part of the crusher changes the most?

Hidrolik Kırıcıların En Çok Aşınan Parçaları

An Engineering Guide To Choosing The Right Breaker

Doğru Kırıcıyı Seçmenin Mühendislik Rehberi

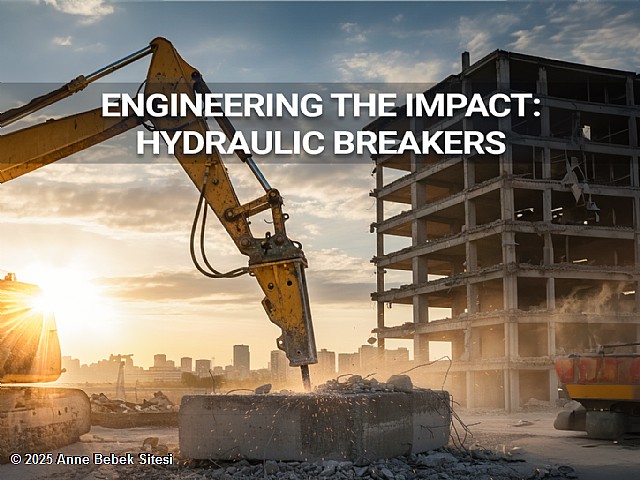

Engineering the Impact: Hydraulic Breakers

Darbeyi Yaratan Mühendislik: Hidrolik Kırıcılar

Hidrolik Kırıcı Yedek Parça Seçerken Dikkat Edilmesi Gerekenler

Ayaklarınızdaki Koku Nasıl Önlenir?

Sabahları Dinç Uyanmanın Püf Noktaları

Konjunktivit; Nedenler, Belirtiler, Önleme Ve Tedavi

Şifa Kaynağı Olan Bu Meyveyi Mutlaka Tüketin

Uyurken Sol Tarafınızda Yatmanızın Sağlığınız Üzerinde Kesin Bir Etkisi Var mı?

Çin Astrolojisine Göre Ben'lerin Anlamı Nedir?

Muzların Sağlık Sorunlarınızı Nasıl Kolaylaştırdığını Biliyor musunuz?

2026© Bu sitenin tüm hakları saklıdır.