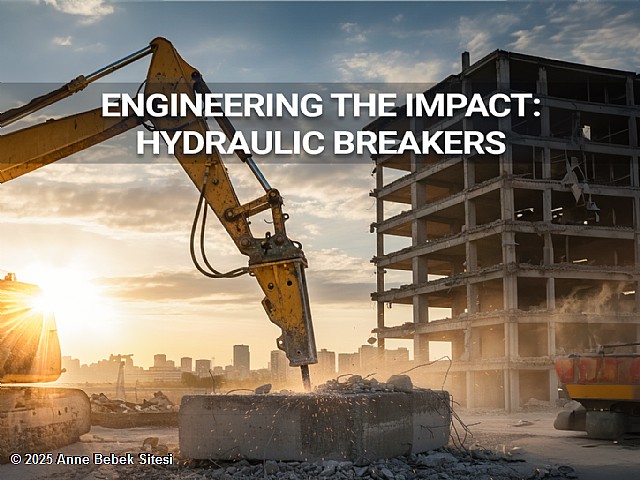

Engineering the Impact: Hydraulic Breakers

Designs vary depending on the brand and model. Some breakers are optimized for higher impact frequency, while others are engineered to deliver greater impact energy.

Engineering the Impact: Hydraulic Breakers

Hydraulic breakers are among the most commonly used attachments in today’s heavy equipment industry. They play a key role in construction, mining, road building, infrastructure development, concrete demolition, rock fragmentation, and recycling applications. Their primary purpose is to deliver high-impact energy onto rock, concrete, or other hard surfaces and break them according to the operator’s needs. The fundamental energy source that generates this impact is hydraulic pressure.

Modern hydraulic breakers are significantly more efficient and durable than previous generations. Understanding how these machines work is crucial for both manufacturers and operators, since proper selection, correct operation, and regular maintenance directly affect their service life. In this comprehensive article, we explain the structure of hydraulic breakers, how hydraulic energy is transformed into impact energy, and the functions of each major component—using clear but technically accurate language.

Basic Structure of Hydraulic Breakers

When simplified, a hydraulic breaker consists of several critical components working in synchrony: a piston moving back and forth, a tool that transmits impact to the ground, hydraulic valves that control piston motion, an accumulator that stabilizes impact energy, a housing that holds the entire system together, and a bushing that manages wear. Each of these components performs a dedicated function and contributes to overall system efficiency.

Designs vary depending on the brand and model. Some breakers are optimized for higher impact frequency, while others are engineered to deliver greater impact energy. Additionally, the hydraulic circuit configuration, the precision of internal mechanisms, and the durability of the housing material significantly influence performance. However, every hydraulic breaker must include five essential components:

- Housing / Body

- Accumulator

- Piston (Breaker Piston / Impact Piston)

- Tool Bushing

- Tool (Chisel / Moil Point)

To fully understand a hydraulic breaker, one must grasp how hydraulic pressure is converted into thousands of joules of impact energy. This transformation is based on the relationship between hydraulic pressure, piston mass, and piston speed.

The carrier machine (excavator, backhoe loader, mini excavator, etc.) supplies high-pressure oil through its hydraulic pump. This oil raises the piston by means of the breaker’s internal valve system. Once the piston reaches the upper position, the system briefly prepares for impact. Then the hydraulic valve shifts direction and forces the oil downward, pushing the piston rapidly toward the tool. During this downward stroke, the piston reaches extremely high velocities. Its kinetic energy is transferred directly to the tool tip, generating a single impact.

For all major components and every other hydraulic breaker spare part you need, visit www.jackhammerparts.com.

Working Fields of Hydraulic Breakers

Hydraulic breakers are among the most essential attachments used on heavy machinery today. They operate across a wide range of applications such as rock breaking, concrete demolition, road excavation, tunneling, demolition works, mining, and quarry operations. Converting hydraulic pressure into impact energy, these tools have become indispensable in modern construction and mining industries thanks to their durability, efficiency, and versatility. Various breaker models have been developed to meet the needs of different machine classes, site conditions, and material types.

Hydraulic breakers are generally classified into three main categories:

1) Large, high-impact breakers for heavy machinery

2) Light- and medium-duty breakers used on compact machines

3) Application-specific custom-designed models

Each category has its own features, advantages, and operational requirements. When selecting a breaker, factors such as the carrier machine’s hydraulic capacity, the working environment, the hardness of the material to be broken, and the operator’s job type must be considered.

Breakers for Heavy Machinery

Hydraulic breakers designed for heavy equipment—such as 20–60 ton excavators—prioritize durability and high impact energy. These breakers are intended for the toughest working conditions, including mining, quarrying, and heavy reinforced concrete demolition.

Typical application areas include: Mining and quarry operations, breaking large rock blocks, post-blasting rock downsizing, fragmentation of hard granite and basalt, opening tunnel entry faces. Models such as Rammer 4099, MTB 285 MR, Epiroc HB 7000, Soosan SQ1900, and Furukawa FXJ770 are well-known for their strength and reliability on extremely hard rock.

Tunneling and Infrastructure Projects

In tunneling and infrastructure works such as opening the tunnel face, preparing the front section for TBM operations, metro tunnels, water tunnels, and wastewater tunnels such as breakers with noise-reduced (silenced) housings are preferred, as low noise levels are particularly important in urban environments. For instance, the MTB 155 TN is a hydraulic breaker that is frequently preferred in tunnel projects.

Heavy Demolition Projects

For large-scale demolition operations including bridge demolition, dismantling of reinforced concrete factories, industrial plant demolition, and breaking large columns and beams, models like the Atlas Copco HB series or Indeco HP 3000–5000 class are preferred due to their combination of impact power and structural durability.

Road Construction and Layer Breaking

In road construction, hydraulic breakers are used for breaking old asphalt layers, fragmenting the rock layer beneath the subbase, and preparing stabilized roadbeds. In these applications, both impact frequency and single-blow impact energy play a critical role.

Diğer Haberler

![Tool Types and Application Areas]() Tool Types and Application AreasOne of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material.

Tool Types and Application AreasOne of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material.![Uç Tipleri ve Uygulama Alanları]() Uç Tipleri ve Uygulama AlanlarıPiston sızdırmazlık sistemi, hidrolik kırıcının darbe üretiminde en kritik unsurlardan biridir. Sızdırmazlık bozulduğunda piston hareketini düzenleyecek basınç farkı oluşmaz ve hız performansı düşer.

Uç Tipleri ve Uygulama AlanlarıPiston sızdırmazlık sistemi, hidrolik kırıcının darbe üretiminde en kritik unsurlardan biridir. Sızdırmazlık bozulduğunda piston hareketini düzenleyecek basınç farkı oluşmaz ve hız performansı düşer.![Critical Components Of The Piston And Impact Mechanism]() Critical Components Of The Piston And Impact MechanismThe piston, regarded as the heart of the impact system, works together with its surface hardness, machining quality, ring design, sealing elements, and in gas-assisted systems the accumulator diaphragm to generate high-frequency energy.

Critical Components Of The Piston And Impact MechanismThe piston, regarded as the heart of the impact system, works together with its surface hardness, machining quality, ring design, sealing elements, and in gas-assisted systems the accumulator diaphragm to generate high-frequency energy.![Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik Parçaları]() Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik ParçalarıDarbenin kalbi olarak kabul edilen piston, yüzey sertliği, işleme kalitesi, kullanılan segman yapısı, sızdırmazlık elemanları ve gaz destekli sistemlerde akümülatör diyaframı ile birlikte çalışarak yüksek frekansta enerji üretir.

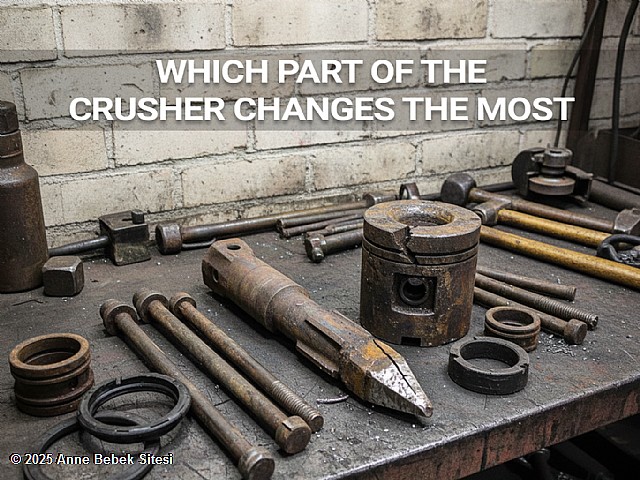

Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik ParçalarıDarbenin kalbi olarak kabul edilen piston, yüzey sertliği, işleme kalitesi, kullanılan segman yapısı, sızdırmazlık elemanları ve gaz destekli sistemlerde akümülatör diyaframı ile birlikte çalışarak yüksek frekansta enerji üretir.![Which part of the crusher changes the most?]() Which part of the crusher changes the most?The wear mechanism depends on multiple factors, including impact intensity, stone and moisture conditions, operating angle, and material type.

Which part of the crusher changes the most?The wear mechanism depends on multiple factors, including impact intensity, stone and moisture conditions, operating angle, and material type.

Tool Types and Application AreasOne of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material.

Tool Types and Application AreasOne of the primary effects is impact energy transfer efficiency. When an incorrect tool is used, impact energy is reflected back into the breaker body instead of being transmitted into the material. Uç Tipleri ve Uygulama AlanlarıPiston sızdırmazlık sistemi, hidrolik kırıcının darbe üretiminde en kritik unsurlardan biridir. Sızdırmazlık bozulduğunda piston hareketini düzenleyecek basınç farkı oluşmaz ve hız performansı düşer.

Uç Tipleri ve Uygulama AlanlarıPiston sızdırmazlık sistemi, hidrolik kırıcının darbe üretiminde en kritik unsurlardan biridir. Sızdırmazlık bozulduğunda piston hareketini düzenleyecek basınç farkı oluşmaz ve hız performansı düşer. Critical Components Of The Piston And Impact MechanismThe piston, regarded as the heart of the impact system, works together with its surface hardness, machining quality, ring design, sealing elements, and in gas-assisted systems the accumulator diaphragm to generate high-frequency energy.

Critical Components Of The Piston And Impact MechanismThe piston, regarded as the heart of the impact system, works together with its surface hardness, machining quality, ring design, sealing elements, and in gas-assisted systems the accumulator diaphragm to generate high-frequency energy. Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik ParçalarıDarbenin kalbi olarak kabul edilen piston, yüzey sertliği, işleme kalitesi, kullanılan segman yapısı, sızdırmazlık elemanları ve gaz destekli sistemlerde akümülatör diyaframı ile birlikte çalışarak yüksek frekansta enerji üretir.

Hidrolik Kırıcılarda Piston Ve Darbe Mekanizmasının Kritik ParçalarıDarbenin kalbi olarak kabul edilen piston, yüzey sertliği, işleme kalitesi, kullanılan segman yapısı, sızdırmazlık elemanları ve gaz destekli sistemlerde akümülatör diyaframı ile birlikte çalışarak yüksek frekansta enerji üretir. Which part of the crusher changes the most?The wear mechanism depends on multiple factors, including impact intensity, stone and moisture conditions, operating angle, and material type.

Which part of the crusher changes the most?The wear mechanism depends on multiple factors, including impact intensity, stone and moisture conditions, operating angle, and material type.